Excavator is a multi-purpose earthwork construction machine that mainly performs earthwork excavation and loading, as well as land leveling, slope repair, hoisting, crushing, demolition, trenching and other operations. Therefore, it has been widely used in road construction such as highways and railways, bridge construction, urban construction, airports, ports and water conservancy construction. So how to choose an excavator that suits your project and choose a high-quality excavator can be judged from the following key factors.

1. Operating weight:

One of the three main parameters of an excavator, it refers to the total weight of the excavator with standard working devices, driver and full fuel. The operating weight determines the level of the excavator and also determines the upper limit of the excavator's digging force.

2. Engine power:

One of the three main parameters of an excavator, it is divided into gross power and net power, which determines the power performance of the excavator.

(1) Gross power (SAE J1995) refers to the output power measured on the engine flywheel without power-consuming accessories such as mufflers, fans, alternators and air filters. (2) Net power: 1) refers to the output power measured on the engine flywheel when all power-consuming accessories such as muffler, fan, generator and air filter are installed. 2) refers to the output power measured on the engine flywheel when the power-consuming accessories necessary for engine operation, generally fans, are installed.

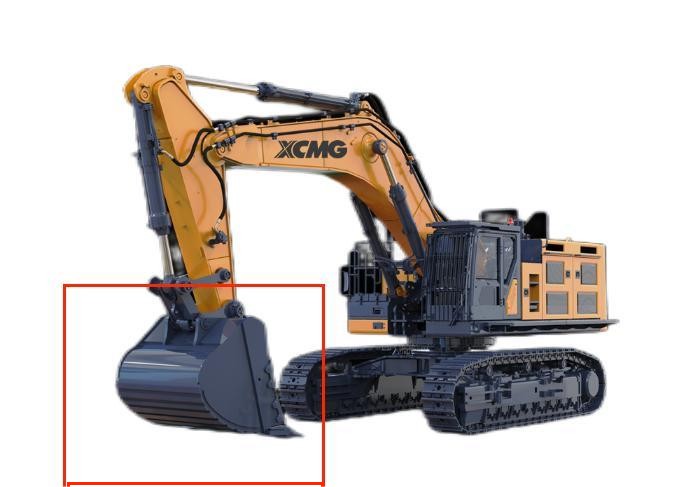

3. Bucket capacity:

One of the three main parameters of an excavator, it refers to the volume of material that the bucket can load. An excavator can be equipped with buckets of different sizes according to the density of the material. Reasonable selection of bucket capacity is one of the important means to improve operating efficiency and reduce energy consumption.

Bucket capacity is generally divided into heaped bucket capacity and flat bucket capacity. The commonly used calibrated bucket capacity of excavators is heaped bucket capacity. Heaped bucket capacity has two types according to the natural repose angle: 1:1 heaped bucket capacity and 1:2 heaped bucket capacity.

4. Digging force

Includes digging force of the digging arm and digging force of the bucket. The two digging forces have different powers. The digging force of the digging arm comes from the digging arm cylinder, while the digging force of the bucket comes from the bucket cylinder.

According to the different points of action of the digging force, the calculation and measurement methods of the excavator can be divided into two categories:

(1) ISO standard: The action point is at the edge of the bucket blade.

(2) SAE, PCSA, GB standard: The action point is at the tip of the bucket tooth.

5. Working range

Refers to the inner area of the line connecting the extreme position points that the tip of the bucket tooth can reach when the excavator is not rotating. Excavators often use graphics to vividly express the working range. The operating range of the excavator is usually expressed by parameters such as maximum digging radius, maximum digging depth, and maximum digging height.

6. Transport size

Refers to the external dimensions of the excavator in the transport state. The transport state generally refers to the excavator parked on a flat ground, the longitudinal center planes of the upper and lower bodies are parallel to each other, the bucket cylinder and digging arm cylinder are extended to the longest length, the boom is lowered until the working device touches the ground, and all openable parts are in the closed state of the excavator.

7. Slewing speed and slewing torque

(1) Slewing speed refers to the maximum average speed that the excavator can achieve when rotating stably when unloaded. The marked slewing speed does not refer to the slewing speed during starting or braking. For general excavation conditions, when the excavator works in the range of 0° to 180°, the slewing motor accelerates and decelerates. When it rotates to the range of 270° to 360°, the slewing speed reaches stability.

(2) Slewing torque refers to the maximum torque that the excavator's slewing system can generate. The size of the slewing torque determines the excavator's ability to accelerate and brake the slewing, and is an important indicator for measuring the excavator's slewing performance.

8. Travel speed and traction

For crawler excavators, the travel time accounts for about 10% of the total working time. Generally, excavators have two travel gears: high speed and low speed. The dual speed can well meet the excavator's climbing and flat ground travel performance.

(1) Traction force refers to the horizontal pulling force generated when the excavator is traveling on horizontal ground. The main influencing factors include the low-speed gear displacement of the travel motor, working pressure, drive wheel pitch diameter, machine weight, etc. Excavators generally have large traction force, which is generally 0.7 to 0.85 times the weight of the machine.

(2) Travel speed refers to the maximum travel speed of the excavator when traveling on standard ground. The travel speed of crawler hydraulic excavators is generally not more than 6km/h. Crawler hydraulic excavators are not suitable for long-distance travel. Travel speed and traction force indicate the maneuverability and travel ability of the excavator.

9. Climbing ability

The climbing ability of an excavator refers to the ability to climb, descend, or stop on a solid, flat slope. There are two ways to express it: angle and percentage: (1) The climbing angle θ is generally 35°. (2) Percentage table tanθ = b/a, generally 70%. The microcomputer index is generally 30° or 58%.

10. Lifting capacity

Lifting capacity refers to the smaller of the rated stable lifting capacity and the rated hydraulic lifting capacity.

(1) Rated stable lifting capacity 75% of tipping load.

(2) Rated hydraulic lifting capacity 87% of hydraulic lifting capacity.

Based on the above information, you can determine which excavator is the best choice based on the engineering working conditions and the technical parameters of the equipment.

Well-known Chinese manufacturers include XCMG \SANY\ZOOMLION\LIUGONG \LONKING \ and other professional manufacturers. You can consult us for the best price!

Post time: Oct-25-2024